Are these the kinds of implants you want to make?

We've got you covered for faster formulating.

Prototype Implants in Hours, Not Weeks

With Just Milligrams of Material.

From concept to clinic, Vacuum Compression Molding (VCM) makes prototyping drug-eluting implants fast and easy. Whether you're exploring new drug formulations or fine-tuning an advanced design, you can create flawless, functional implants with only milligrams of material—right on your lab bench. No scale-up risk, no wasted API, no steep learning curve. Just reliable, replicable results in record time.

Book a Free Demo!

Researchers Formulating Implants

with VCM Technology

VCM Technology is engineered to meet the demanding requirements of implant development, offering precise control over material properties and structure. Explore the peer-reviewed publications to learn more about how VCM is being applied in implant-focused research and development.

From Powder to Implant Prototype with VCM

With just a few milligrams of material and a compact platform that fits on a one-meter lab bench, you can produce flawless prototypes – quickly, cleanly, and without any material loss. Let’s walk through the journey, from powder to prototype.

Step 1: Preparing Your Formulation – Prototype with Just Milligrams!

Start with your homogeneously mixed formulation, whether it’s a powder, granulate, or blend. Thanks to VCM’s low material requirements, you can prototype quickly while minimizing waste. Need tips on how to get the best results? Check out our Mixing Guide.

Step 2: Know Your Formulation’s Thermal Traits for a Flawless Process

Thermal analysis of your material is fast and straightforward with the MeltPrep Slider. This user-friendly add-on requires no calibration, making it easy to get started right away. You can visually observe the glass transition temperature (Tg) and degradation with the naked eye, allowing for quick assessments without complex equipment.

Step 3: Calculate the Material Needed for Your Implant Prototype

Now that your material is ready, how much do you need? VCM Calculators provide the exact amount for each standard geometry, from mini implants to larger depot systems. Precise dosing ensures perfect fills with no waste and no excess material.

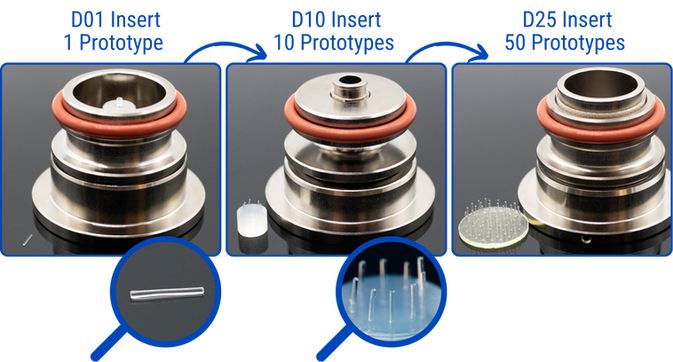

Step 4: Load and Mold with Your Prototype Geometry

Now simply fill your chosen insert chamber with the formulation designed for the prototype geometry you need. If you’re unsure which insert chamber best fits your application, feel free to reach out. We’re happy to assist or provide a free demo to help you find the perfect match.

Pharma Pro Suitcase: All Standard Geometries Ready to Go

The Pharma Pro Suitcase comes fully equipped with all the standard implant geometries you need—twice over for maximum efficiency. This ready-to-use tool kit is designed to streamline your formulation process, providing a convenient, all-in-one solution that fits perfectly into your development workflow.

Versatile Prototyping with Pharma Pro

The Pharma Pro Suitcase enables Free-D molding and, with interchangeable inserts, supports a variety of molds to produce either single or multiple implant prototypes with ease.

Free-D Molding: Custom Prototype Geometries

Need a custom shape? With Free-D Molding, we turn your unique designs into precision molds that fit seamlessly into our VCM insert chambers. Because the Pharma Pro Suitcase includes all standard geometries—twice over—it gives you everything you need to support custom mold development and integration.

That means you can quickly and easily produce exact prototypes using the same fast, efficient VCM cycle used for standard forms. No matter the shape, Free-D Molding lets you bring innovative, tailored delivery systems to life for precise screening and development.

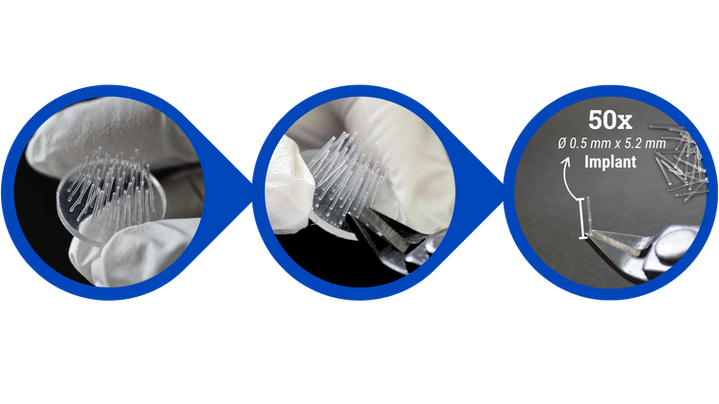

Small Feature Sizes with Free-D Molding

Free-D molding enables the creation of ultra-fine features, down to sizes as thin as a human hair, delivering exceptional precision in microscale manufacturing.

.png)

.png)

.jpg)

Rounded Edges

Step 5: Scale Up with Free-D Molding and 100+ Implants Per Batch

It’s not just prototyping. It’s your entire early-stage development, wrapped up in one compact, flexible platform. From powder to prototype and beyond. With VCM, your implant development journey has never been simpler, faster, or more precise.

Once your formulation is dialed in, the same Free-D molding system can be used to scale up and produce clinical batches. That means no transfer to new manufacturing processes, no reformulation, and no extra steps, just a straight path from early testing to clinical use.

GMP-Ready When You Are

When you're ready to move from prototyping to clinical manufacturing, we’ve got you covered. All standard implant geometries developed with VCM are also available in GMP-grade formats so you can seamlessly transfer your validated prototype into regulated production. No redesigns, just a clear path from lab bench to batch release.

Which Dimension Works Best for You?

Talk to our experts and see which prototype dimensions are the right fit for your project.

Step 6: Scale Up with Extrusion

Prototyping implants using the VCM platform allows for a smooth transition to large-scale manufacturing using extrusion technology. In a collaborative case study by Ashland, MeltPrep, Queen’s University Belfast, and Leistritz, implant formulation began with the VCM platform.

Initially, VCM was used to identify the optimal polymer. Once selected, the polymer samples were sent to Queen’s University Belfast, where they were loaded with the API and reshaped into VCM samples for analysis. The resulting data was then provided to Leistritz to develop a full-scale manufacturing process using hot melt extrusion (HME).

The case study data includes a direct comparison between prototypes made with VCM and those produced via HME. The release profiles from both methods are nearly identical, confirming that scale-up from VCM to HME is seamless.

Turn Your Ideas Into Implants: Book a Free Demo

Ready to see VCM in action? See how fast and simple implant prototyping can be. Book your free demo today and let our team help you turn your ideas into precision implants, no matter if you're just starting out or looking to accelerate development.